The modular (endoskeletal) design of the lower leg prosthesis consists of: a stump sleeve (with a soft liner and /or with a silicone cover (liner)), a sleeve adapter (support), a carrier module, a clamp sleeve, a foot module, a cosmetic shell and a cosmetic coating.

In turn, the bearing module and the clamping sleeve can be either without or with additional functions of torsion and/or vertical shock absorption. In some designs of clamping bushings, the function of changing the height of the heel can be implemented.

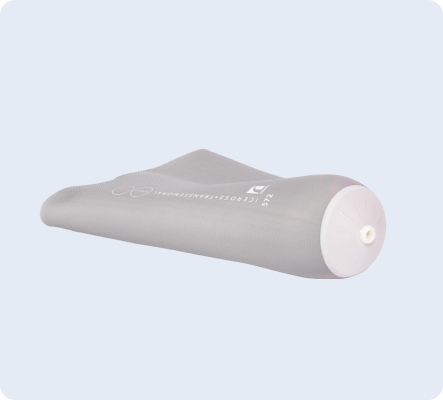

The foot modules are very diverse, both in terms of design, appearance, implemented functions, and in terms of price, which gives a chance to almost completely satisfy the needs of even the most sophisticated patients. Some modules of the foot have the ability to adjust the height of the heel.